Best Sand Blasting Machine Manufacturer in India | Gritblast

Sand blasting is used essentially to clean the exterior of any material, mainly for the metal surface. This is probably the most effective and fastest strategy that uses packed air to blast fine sand through the spout onto the smooth surface of any unknown material. It is suitable for removing rust that damages property. It is not used specifically to remove rust, but to obtain a finished surface for better coating with 'Sand Blasting Machine' or to achieve the final result so that the retail buyer can get shine and surface. The materials used to influence the sand are sand, copper treasure, roughness of steel, pieces of walnut, dust screen, pieces of avocado and many more.

In addition, the sand has a high moisture content, which can

indicate a premature collapse affecting the hardware. Instead of sand, we use

steel layer to remove paint sand oxide layers from the thick metal surface and

we can damage the crushed glass to get a clearer surface, in case we use other

heavy materials.

What is a Sand Blasting Machine?

This machine is used to clean paint, rust, and some other

types of contaminants, possibly from the metal surface. Sand

blasting machine is the types of gears that are used to

clean mechanical aid with silicone sand that works under great stress. It is

mainly material in yachts, structures and various vehicle companies. This

interaction helps mainly with forest losses and gives the material flawless

before covering it with a protective layer and for this the cycle becomes

fundamental on all the metal formation before it tries to cover. There are

different techniques for cleaning grates, although the sand surface is the most

effective strategy for cleaning metals.

This cycle has some different functions, such as that it is

additionally used to make a sign on wood and glass to give it a valid shape.

Many hotels and resorts use this type of signage to make their items look

traditional and ugly. This high pressure factor machine is also used to mark

cemeteries.

However, the main use of this machine is to clean vessels

such as metals used in the block, stone, development and concrete works

industries.

Sand Blasting Machine Process:

Sand blast machine interacts to lubricate an unsightly

surface, a strong push of a grid material at the bottom of the gun to smooth

out an unsightly surface. A liquid compressed air or rotating wheel (turbine or

motor) is compressed by It is used to push the shooting material towards the

subject. This cycle mainly helps prevent damage and consumes the material

before covering it with a protective layer and for this the all-metal elemental

design is found before attempting to cover this interaction. There are

different strategies for cleaning abrasive

media, but sand blasting is the strongest strategy among them for cleaning

metal surfaces.

This cycle has a few different functions, such as the one

used to make wood and glass signs to give them a reliable look. This high pressure

machine is similarly used to consume signs in cemeteries.

Steps Involved in Sand Blasting Machine:

The initial phase in this cycle is to decide the sort

of material and gear that are important to finish the undertaking. Guarantee

that there is no buildup on surface on which you will be filling in as it

might bring about defaced finish. Break down the level of work, sort of blasting

material and what instruments should be utilized. Guarantee that all security

attire is accessible.

Prepare your encompassing territory to maintain a strategic

distance from a pointless wreck. Launch?? Characterize measure this cycle

requires practice prior to having the option to play out the assignment

appropriately.

Sand Blasting Machine Types:

Two kinds of sandblasting machines are utilized generally:-

Portable Sand Blasting Machine:

Portable sand blasting machine is a sort of sand blasting machine is versatile so

these can be moved starting with one spot then onto the next. These are

generally discovered introduced on the semi-trailers to take on various areas.

Furthermore, assuming you utilize a lighter rendition of this machine, these

are simpler to utilize and you can uninhibitedly move them. The blast machines

are basically utilized in huge businesses.

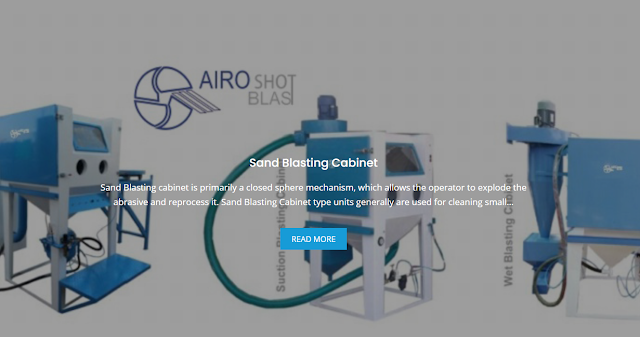

Cabinet Type Sand Blasting Machine:

Cabinet type sand blasting machine is another kind of sand blasting

machine which has a bureau and is a shut type of the machine. In that shut part

blasting of impurities just as changed over happens. There are different

capacities which are incorporated like cleaning, reusing just as the assortment

of residue materials as well. So sand blasting

machine price in India influence on all assembling enterprises hardware

cost.

Sand Blasting Machine Components:

•

Blast nozzle

•

Moisture trap

•

Deadman switch

•

Air compressor

•

Blast pot

(pressure blast tank)

•

Abrasive (blast

media)

•

Blast hood

•

Interconnect

hoses

Use of Sand Blasting Machine:

The lettering and blast on most present day burial ground

stones and markers are made by a rough sand blaster machine. Eliminate

"blazing" (abundance material) from shaped plastic or elastic. Sand blasting machine equipment

likewise is utilized to give three-dimensional signage this kind of signage is

required to be a better quality item when contrasted with level signs.

Clean a surface by eliminating undesirable rust, scale,

paint, and so forth, in anticipation of painting, anodizing, welding, or

different cycles that require a perfect surface. Debar, eliminate tooling marks

or diversely finish a rough item.

Sand

blasting process are utilized for cleaning boat outlines, just as block

stone, and solid work. Give a genuine cutting or engraving of halfway veiled

parts, like headstones.

Change metallurgical properties or stress mitigate a section

by the preening activity of different bastions. Produce the ideal matte or

enlivening completion.

Sand Blasting Machine Price:

The price of a sand

blasting machine depends on the extent of the tank pressure factor and the

time it takes to wrap. Relative to industry experts, the sandblasting machine

is an important piece of gear for sandblasting. Owners of mechanical offices,

shipyards, railways, and others require strong pressure factor firing hardware

for cleaning and erosion control.

These multi-cause machines are important and require a

specific level of capability and good care to function, although the components

of an actual machine are usually sufficient to be easy to understand.

Sand Blasting Machine Price in India:

The price of sand blasting

machine in India depends on the type of equipment. It is a good driving

strategy to adjust the mids at high speeds to produce a wide variety of

results. It is used for various cleaning, scrubbing, paint and coating

finishing, injection and wrapping strategies.

Sand Blasting Machine Manufacturer:

Gritblast is the largest sand blasting

machine manufacturer in India. Sand blasting machines are pieces

of equipment used to help clean silicon sand that operate under high stress.

This machine is commonly used to clean paint, rust, and some other types of

contaminants from the metal surface. It is basically applied in boats,

structures and various vehicle undertakings.

There are different techniques for cleaning grating, although

sand blasting is the strongest

strategy among them for cleaning metal surfaces.

This interaction primarily helps prevent damage and

introduces perfection before covering the material with a protective layer and

for this it achieves the original all-metal design before attempting to cover

the circle.

Sand Blasting Machine Manufacturer in India:

Sand blasting machine manufacturer in India. The sand blasting machine can be

characterized as a cleaning cycle and the material can be completed or

suspended in a liquid medium, with a powerful bearing of rough media applied to

any medium.

Sand is regularly used to clean iron or steel surfaces. The

various surfaces commonly used by sand blasting

process include workmanship (blocks, stone, concrete, etc.), sand cast,

aluminum, copper, metal, wood, glass, and plastic.

Best Sand Blasting Machine Manufacturer in India:

GRITBLAST is among

the other sand blasting machine

manufacturers and suppliers in Jodhpur, Rajasthan. We manufacture and ship a wide range of sand blast

machines across India. The price of machines is the best among the remaining

providers. The best price for machines as the ideal machine management,

customer compliance is our first approach.

Comments

Post a Comment